Lo que hacemos

La palabra clave - “resolver”, se puede usar literalmente. En la mayoría de los casos, el agua no causa los problemas. Si no cuando ciertas sustancias o materia se asienten sobre las superficies interiores de tuberías o máquinas, el problema se vuelve costoso y difícil. Mientras los sólidos se disuelvan en el agua, no causan ningún daño.

Le ofrecemos asesoría y apoyo para eliminar incrustaciones, corrosión, o biopelícula en sus tuberías, independientemente del tamaño de su problema.

Por cierto, nuestro ablandador de agua alternativo es el golpe.

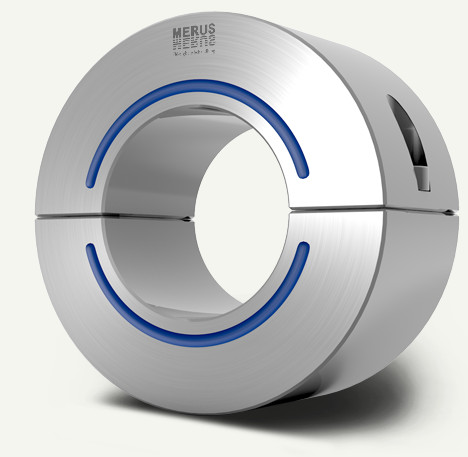

Nuestro Anillo Merus

Con el Anillo Merus sobre la tubería, se puede aumentar la solubilidad de los minerales en el agua.

Esto significa, por ejemplo, que una mayor cantidad de calcio se mantiene disuelto en el agua y continúa fluyendo con ella, en lugar de obstruir tuberías y válvulas.

¿Cuál es el truco? Aprovechamos la oscilación natural, que caracteriza a cada sustancia. Esta puede ser modificada a nuestro favor con ondas superimpuestas.

Esta metodología de tratamiento de agua no requiere aditivos químicos y tampoco es necesaria una fuente de energía eléctrica. Al no tener ningún tipo de efecto secundario, es ideal para el agua potable, así como el agua de uso industrial.

Para agua potable limpia.

Estamos celebrando el 25° aniversario de Merus.

Donaremos 20€ por cada anillo vendido para apoyar a Viva con Agua Sankt Pauli e.V.. Su objetivo es dar acceso a agua limpia y potable, así como facilidades sanitarias básicas a todos los seres humanos en el planeta.

Agradecemos a todos nuestros clientes por su confianza en nosotros y en el Anillo Merus.